We use cookies to analyze our website traffic and to understand where our users are coming from.

Safety

There is a lot to consider and a lot of harm can be done when underestimating the consequences of safety issues. We described the essential criteria, which ensures that you receive a fault-free cable. Your employees will never be in danger. Sometimes a picture says more than a thousand words! We take it seriously!

Recommendation for storage and transport of cables

General

Depending on the choice of cables and the laying conditions, adequate protection against mechanical damage and solar radiation must be provided. If cables are stored at temperatures below the recommended laying temperature, they should not be subjected to mechanical stresses, including vibrations, impacts, bending stresses and twisting.

Free space

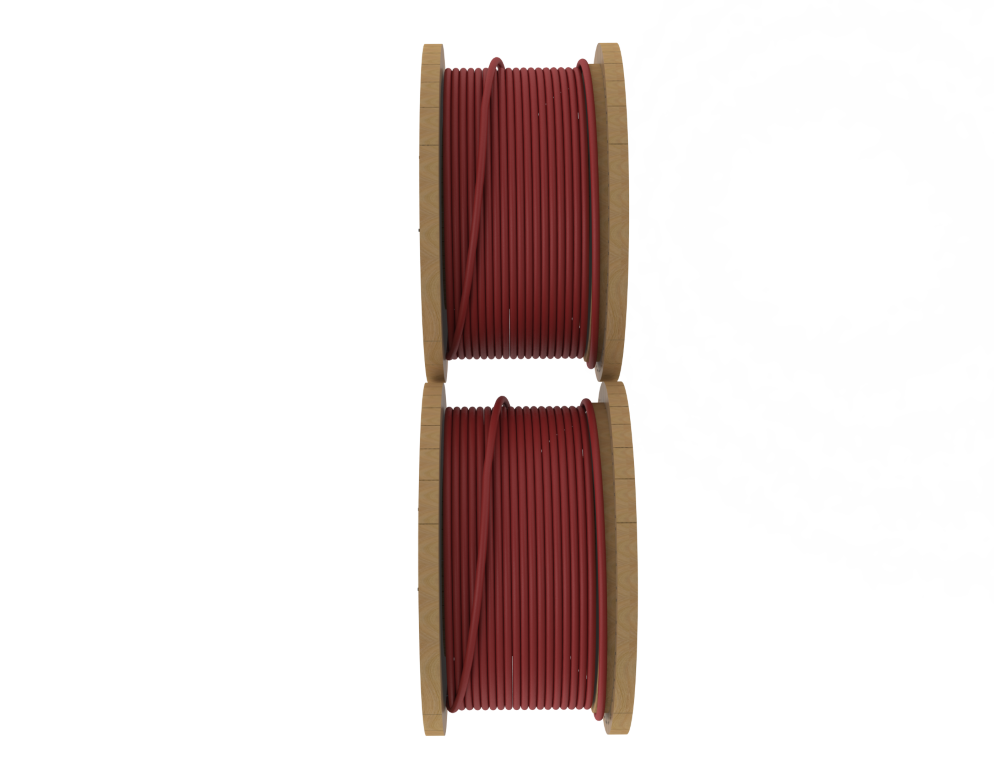

Make sure that there is enough space between the outer layer and the casing. An incorrectly wound cable can also sag and take undesirable damage from touching the ground.

Core diameter

The core diameter of the coil should at least correspond to the permissible bending radius.

Cable sealing

The cable ends should be sealed against moisture with appropriate caps and regularly checked or repaired.

Handling

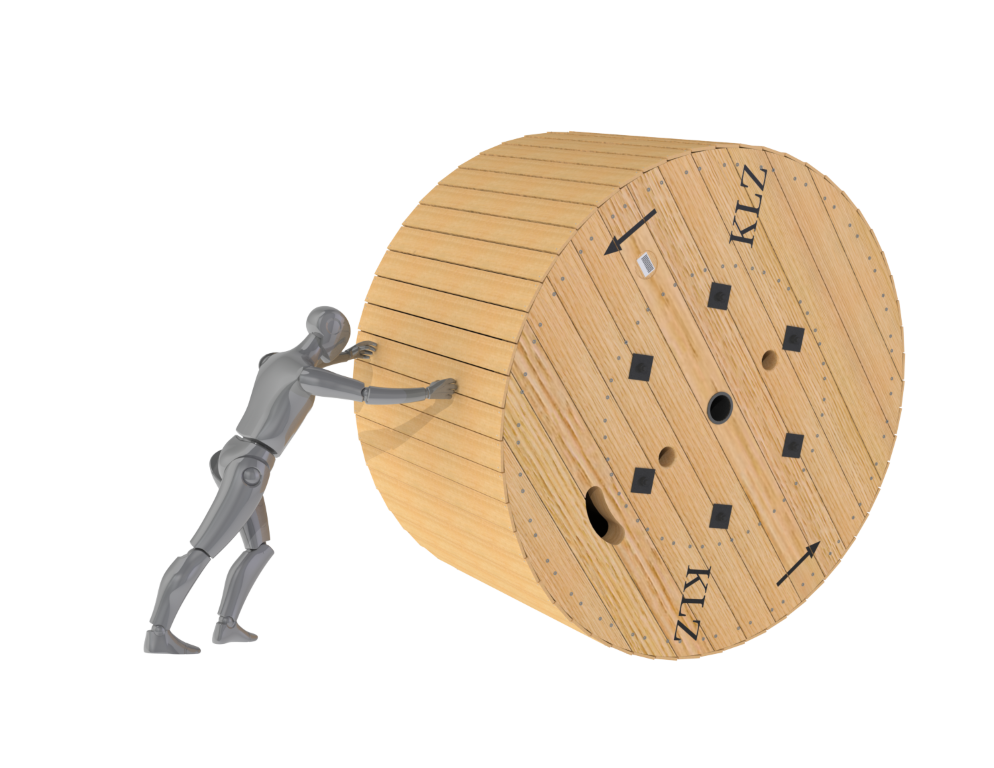

When handling coils, the necessary precautions should be taken to avoid damage to the cable and personal injury. The mass of the spool, the movement and the direction when rolling as well as the lifting procedure must be taken into account with the appropriate care.

Coil condition

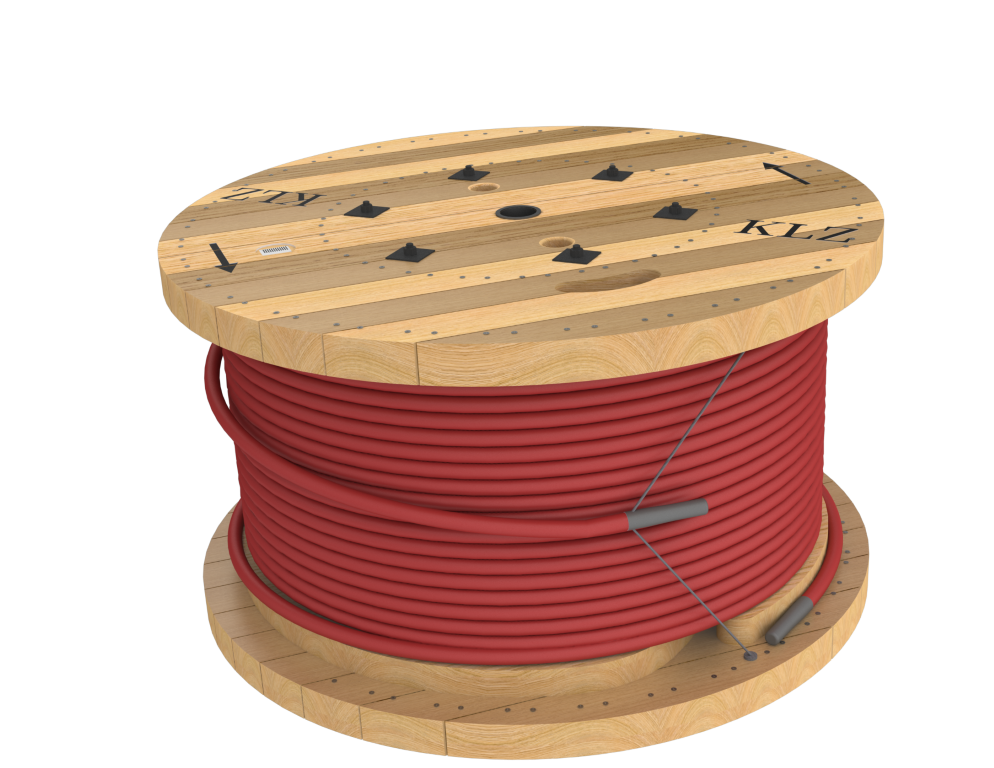

Pay attention to the condition of the spool when storing the cables. Especially on protruding nails and staples. Cable reels should be stored in such a way that the flange do not touch cables from other reels.

Cable reels should be stored with the reel axis horizontal.

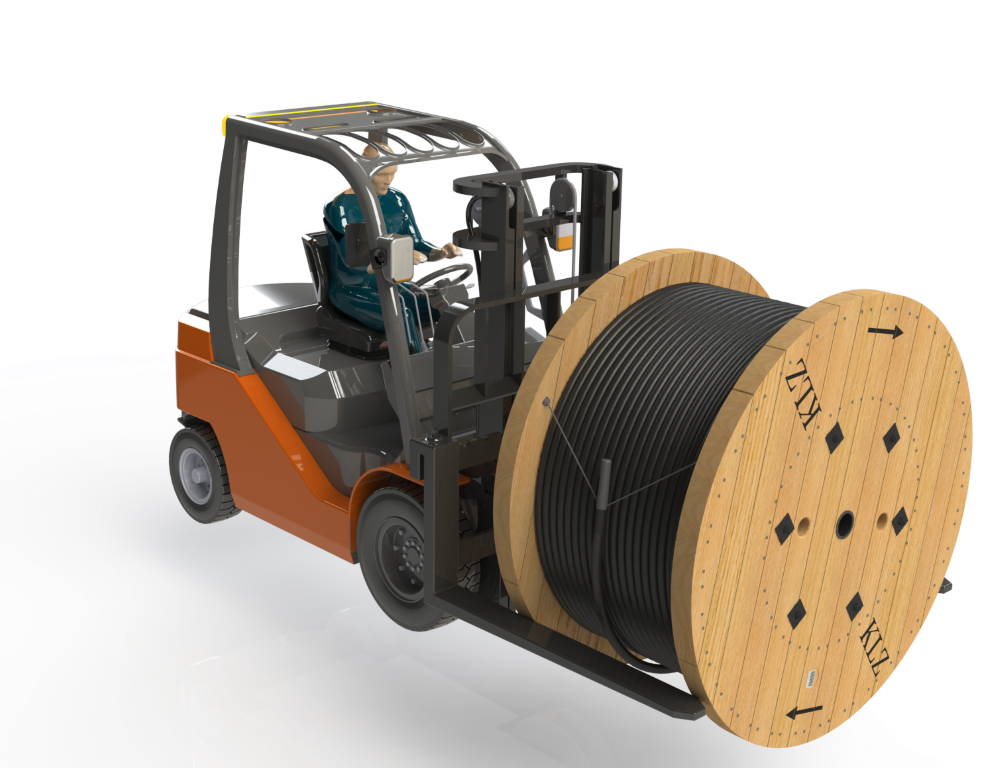

Transport / vehicles

Only suitable vehicles should be used.

Position of the coil axis:

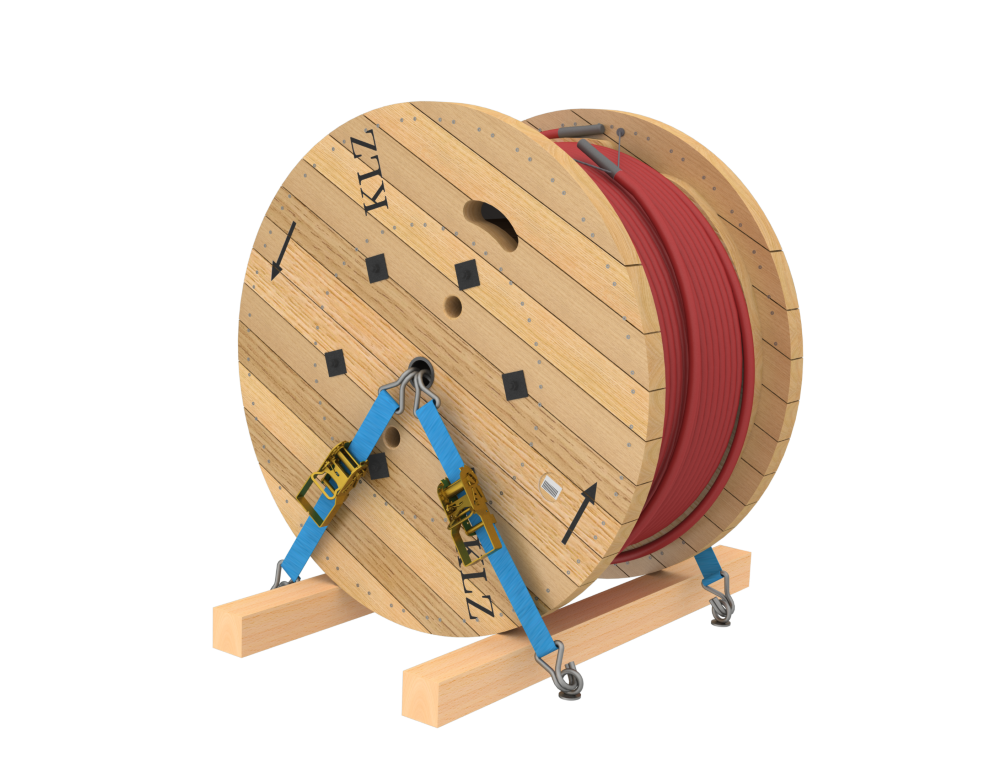

Cable reels should be transported with a horizontal axis, any (uncontrolled) movement of the reels should be avoided.

Loading and unloading

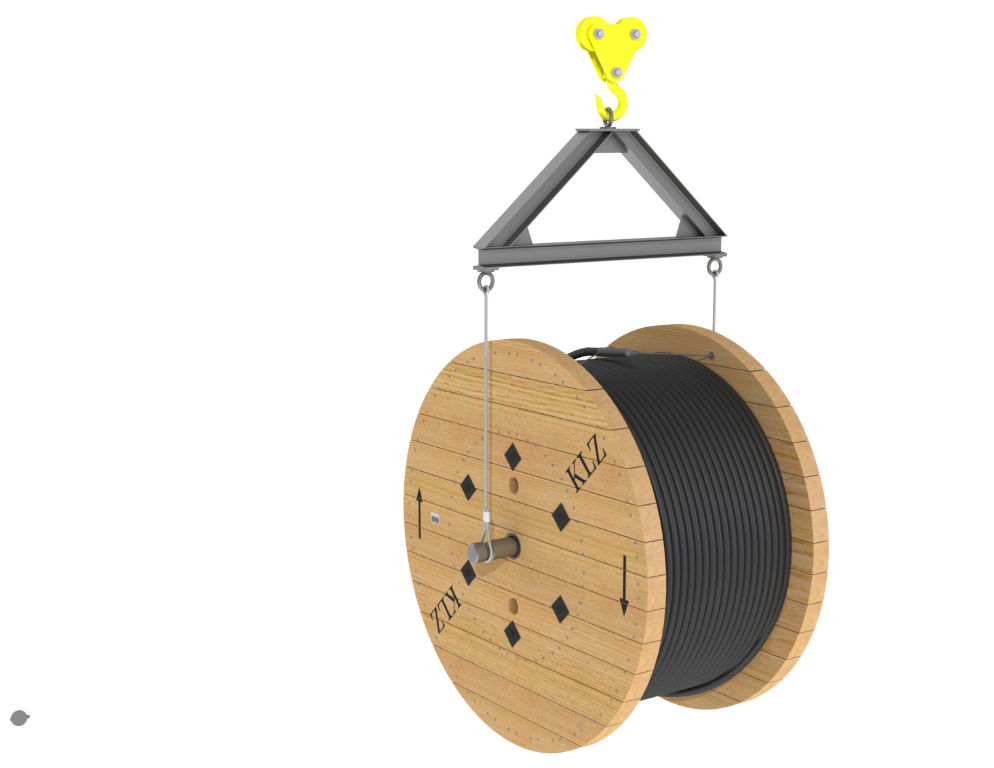

Suitable lifting and crane vehicles are to be used for loading and unloading cable reels. A spool must be carefully unloaded and must never be dropped.

Spools should be unloaded using a crane or forklift truck.

Rolls of cable reels

Cable reels should only be moved over short distances on firm, level ground in the direction indicated on the reel disc.

Fixing the cable ends

Cable ends should also be securely attached to the spool during transport and storage.